Fondation Inartis

29 January 2019

No Comments

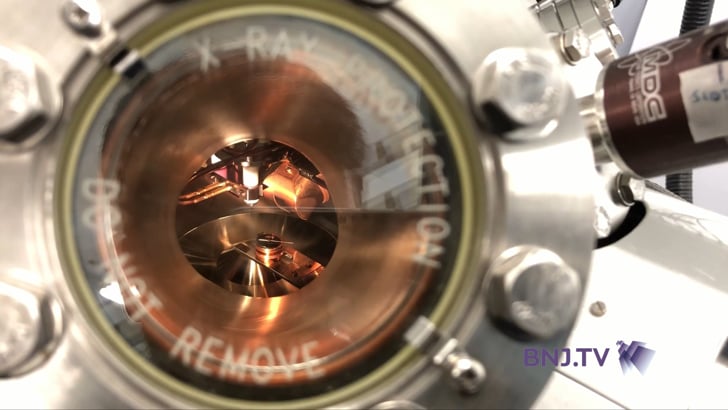

Impulse Current Bonding technology

Discovered in 2016, this technology now makes it possible to bond different varieties of glass to metals such as stainless steels, medical titanium and superconducting alloys. CBE also makes it possible to bond technical ceramics to metals.

This discovery was initiated as part of a CTI project between HE-Arc and a Swiss luxury watchmaking group to provide a solution and innovation in the problem of assembly. It is an innovative breakthrough technology; it allows perfect bonding at the atomic level between substrates and therefore does not require the use of adhesives, solders or any other binder.

This joining method, known as ICB, is now part of the high-tech microtechnology assembly group (bonding in microsystem technology) and offers completely new alternatives to the traditional techniques of anodic bonding or direct bonding. The new ICB technology is a low-temperature process that allows the bonding of materials with very different coefficients of expansion. Not very sensitive to dust and to the state of the surfaces, this bonding process between substrates is currently carried out in an industrial environment and thus frees itself not only from a controlled environment but also from the polishing stage.

Multiple applications

The CBE concerns all companies that assemble glass or ceramics to metals. Thus, the scope of CBE assembly is unlimited and finds its place not only in cutting-edge sectors such as aerospace or biomedical but also in the manufacture of more common goods.

The Pharmaceutical market

SY&SE proposes to bind materials usually used in the biomedical and pharmaceutical sectors. Steel 316L, medical titanium, glass are privileged materials in these environments.

From a biotechnological point of view, the interest of CBE is based on the fact that the bond obtained resists the following exposure cycles:

It withstands exposure to toxic gas in the plasma phase

It can withstand the steaming process

It is resistant to UV X-rays and alcohol disinfection

Pictures

Team

Sébastien Brun et Florian Telmont.